Hunters Specialties Blade Driver TV commercial - Wafer Blade System Video

Advertisers

Advertisers of the Hunters Specialties Blade Driver TV Spot, 'Wafer Blade System Video'

Hunters Specialties

Hunters Specialties is a renowned company that specializes in offering top-of-the-line hunting gear and accessories. With a rich history and a commitment to quality, the company has become a go-to bra...

What the Hunters Specialties Blade Driver TV commercial - Wafer Blade System Video is about.

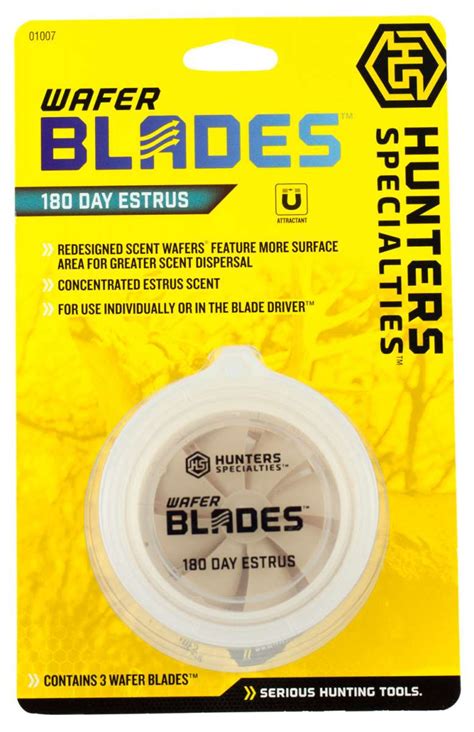

The Hunter's Specialties Blade Driver TV spot features a powerful and innovative Wafer Blade System that promises to revolutionize the hunting industry. The commercial opens with stunning footage of a hunter in the wilderness, armed with the Blade Driver and ready to take down his prey.

As the hunter creeps through the brush, the commercial explains the science behind the Wafer Blade System. This system utilizes a unique wafer-thin blade design that is meant to deliver deadly accuracy and penetration with every shot. The blades are made from high-quality steel and are incredibly sharp, making them highly effective for taking down game.

The commercial then showcases footage of the Wafer Blade System in action, with close-up shots of the blades slicing through targets with ease. The system is shown to be both efficient and effective, giving hunters the confidence they need to take on even the toughest prey.

The Hunter's Specialties Blade Driver TV spot is an impressive showcase of the Wafer Blade System and its capabilities. It highlights the technology's ability to deliver unmatched accuracy and precision, making it a valuable tool for hunters all over the world.

Hunters Specialties Blade Driver TV commercial - Wafer Blade System Video produced for Hunters Specialties was first shown on television on July 4, 2016.

Frequently Asked Questions about hunters specialties blade driver tv spot, 'wafer blade system video'

Videos

Watch Hunters Specialties Blade Driver TV Commercial, 'Wafer Blade System Video'

Unfortunately we were unable to find any suitable videos in the public domain. Perhaps the video of this TV commercial has not been preserved. If you know the link to this commercial, you can send it to us using a special form.

Products

Products Advertised

TV commercials

Similar commercials

![2019 Jeep Grand Cherokee TV Spot, 'The Many, the Few' Song by SUR [T1] 2019 Jeep Grand Cherokee TV Spot, 'The Many, the Few' Song by SUR [T1]](https://connect4productions.com/image/2019%20Jeep%20Grand%20Cherokee%20TV%20Spot,%20%27The%20Many,%20the%20Few%27%20Song%20by%20SUR%20%5BT1%5D/tv)