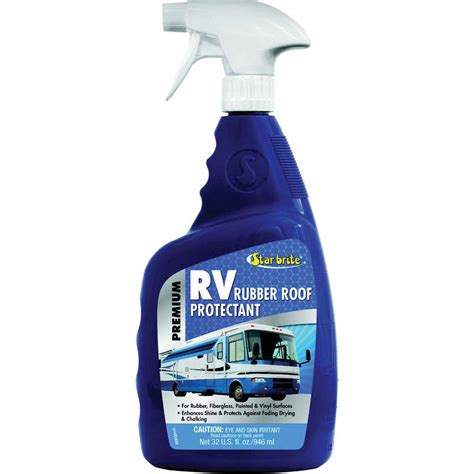

What is Star Brite Premium RV Rubber Roof Protectant?

Star Brite Premium RV Rubber Roof Protectant is a product designed to provide superior protection for the rubber roofs commonly found on recreational vehicles (RVs). This protectant is formulated to shield the roof from the damaging effects of UV rays , dirt, grime, and other environmental elements.

Protection and PreservationStar Brite Premium RV Rubber Roof Protectant serves as a barrier against harmful UV rays , which can cause fading and deterioration of the roof material over time. By applying the protectant, the rubber roof is shielded from the sun's rays, helping to prevent cracking, peeling, and other forms of damage.

In addition to UV protection, this product helps repel stains and keeps the rubber roof clean and vibrant. It forms a protective film on the surface, making it easier to clean and maintain. Regular use of the protectant can extend the life of the RV roof.

Easy ApplicationApplying Star Brite Premium RV Rubber Roof Protectant is a straightforward process. It comes in a convenient spray bottle or can be used with a sponge or cloth. Simply spray or apply the protectant to the rubber roof, spreading it evenly across the surface. The product works on both new and older rubber roofs.

Compatibility and VersatilityThis RV rubber roof protectant is compatible with all types of rubber roofs commonly found on recreational vehicles , including EPDM, TPO, and PVC roofs. It is specifically formulated to adhere to the rubber surface and provide long-lasting protection.

ConclusionStar Brite Premium RV Rubber Roof Protectant is a reliable product for maintaining and protecting rubber roofs on RVs. Its UV protection properties , stain repellency, and ease of application make it a popular choice among RV owners. By regularly using this protectant, you can extend the life of your RV's rubber roof and keep it looking great for years to come.

Frequently Asked Questions about star brite premium rv rubber roof protectant

The most common are rubber membrane roofs (EPDM/TPO) and fiberglass roofs. Rubber roofs are made of a thin weatherproof membrane that is stretched across a wooden substrate. Fiberglass roofs are molded and it's best to keep them waxed so anything that lands on the surface will slide right off.

Roof-Gard Protectant is ideal for all RV roofs – including rubber, vinyl, PVC, TPO and fiberglass. Its mild, non-abrasive formula keeps surfaces cleaner longer with no residue or oily build-up. Simply spread even with a mop or cloth and let air dry.

Because they're so durable, rubber roofs are also able to withstand high winds and hail damage. Another distinct advantage of rubber roofs for RV's is that they're easy to seal and repair if they ever happen to become damaged. Repairs of rubber roofs tend to be fast, easy, and cheap.

RV roofs, especially rubber ones, should be cleaned several times a year. Cleaning is essential for maintaining the roof's appearance as well as its longevity. Never use cleaners that are made with petroleum solvents, abrasives, or citrus ingredients as these can weaken the strength and bonds of the materials.

Rubber roof coatings have a Class A fire rating, meaning they are fire-resistant, as well. Reflective. Coatings' reflectiveness can save up to 40% in energy costs. Inland's white roof coatings reflect UV rays away from the building, keeping the roof and building cool.

Rubber is most commonly used on low-sloped and flat roofs, as it offers a watertight seal that protects these kinds of roof from water damage better than traditional shingles. Of course, this material also offers different benefits to traditional roof shingles.

You don't need to coat a rubber roof. The EPDM membrane is a waterproofing sheet and is the final and top layer.

Rubber roofing is resistant to temperature extremes – whether it's freezing or hot, rubber roofing will not be prone to cracking. It's also not a combustible material, because it's hard to burn. Though it can be punctured, there are few flaws in rubber roofing over other roofing materials.

It is typically installed using a single, seamless sheet, rather than installing many layers of your chosen roofing material. Rubber is most commonly used on low-sloped and flat roofs, as it offers a watertight seal that protects these kinds of roof from water damage better than traditional shingles.

Motion. It works best if you work in three by three foot sections at a time after cleaning a section of the roof rinse with water. It may be necessary to repeat the process on stubborn.

Coating the roof with sealant regularly ensures that you can extend the life of the roof, and often the life of the vehicle in general. RV rubber roof coating is easy for even a new DIY handyman to apply.

Rubber coating is applied to seal tools, flooring, and various other surfaces. The rubber coating is liquified having consistency of glue.

Roof coatings are formulated to protect roofs from the damaging effects of weather and the environment, such as UV light, and excessive water and wind. They are formulated to provide protection for many years and are also extremely elastic; they typically contain a high level of top-quality resin.

Polyvinyl chloride (PVC) and ethylene propylene diene monomer (EPDM) are among the common variants of this type of rubber roofing. A century ago, most flat roofs were made of built-up roofing (BUR).

Like any type of motor vehicle, RV roofs are built to withstand tough weather, from snow to hail to a deluge. However, the roof material can still wear out over time. Coating the roof with sealant regularly ensures that you can extend the life of the roof, and often the life of the vehicle in general.

Silicone roof coatings are the preferred choice when it comes to UV protection and resistance to ponding water. They erode much slower than other coatings without becoming brittle or hard. Modern silicone formulations have a high-solids content that typically exceeds 90 percent.