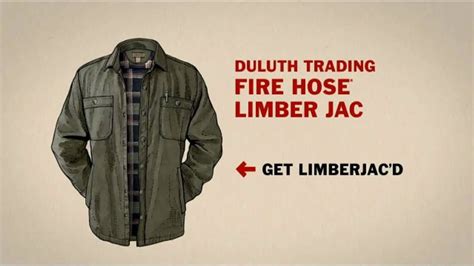

What is Duluth Trading Company Fire Hose Limber Jac?

Duluth Trading Company is known for creating high-quality workwear that is both rugged and practical. Their Fire Hose Limber Jac is no exception - it's made to be tough enough for a day's work, but flexible enough to keep you moving.

The Fire Hose Limber Jac is made from their proprietary Fire Hose canvas, which is a blend of high-quality cotton and nylon that's incredibly durable. This canvas is then prewashed and softened for a comfortable fit that doesn't sacrifice toughness.

One of the things that sets the Limber Jac apart is its flexibility. It features underarm gussets that allow for a full range of motion, so you can bend, reach, and lift without feeling restricted. The sleeves are also articulated to ensure that they don't ride up when you're hard at work.

The Limber Jac is designed with utility in mind. It has plenty of pockets to keep your tools and gear organized, including two chest pockets with snap closures and two hand pockets with hidden snap closures. Additionally, the Jac has a locker loop on the back of the collar that makes it easy to hang up and store.

Finally, the Limber Jac is available in a range of sizes, so you can find the perfect fit for your body. The sizing is consistent with other Duluth Trading Company clothing, so if you know your size in another style, you can feel confident that the Limber Jac will fit the same way.

Overall, the Duluth Trading Company Fire Hose Limber Jac is a versatile and durable workwear option that is designed to keep hardworking folks comfortable and productive on the job.

Frequently Asked Questions about duluth trading company fire hose limber jac

Fire Hose 100% cotton canvas makes them incredibly durable yet soft, with a prewashed, broken-in feel right out of the box. They repel water and stains, thanks to the FendOff Finish™ fabric treatment.

A single jacket hose has one cover protecting the inner rubber liner and a double jacket hose has two covers to protect the liner for increased durability and sometimes water pressure rating.

In Amsterdam in the Dutch Republic, the Superintendent of the Fire Brigade, Jan van der Heyden, and his son Nicholaas took firefighting to its next step with the fashioning of the first fire hose in 1673. These 50-foot (15 m) lengths of leather were sewn together like a boot leg.

The standard three sizes of hose lines are 1½, 1¾ and 2½ inch. Depending on the size and severity of the fire, hose line requirements vary to get the job done efficiently. Selecting the incorrect one from the start can cause delays in fire suppression and exhaustion.

Nylon and polyester yarns are woven, sometimes together, on a circular loom to form a hose jacket. The threads that run lengthwise up and down the hose, forming the inner and outer surfaces of the jacket, provide abrasion resistance.

Without a jacket, the rubber tube would be very prone to bursting from the fast-moving fluid. This type of jacket construction is best used for hosing down equipment, standpipe systems (hose cabinets), forest fires, and other applications that require more maneuverability.

Today, most fire hoses are made of a nitrile rubber tube that is insulated by a woven polyester fabric jacket instead of the cotton fire hose canvas used in the past.

A data firehose, or a data stream, is a continuous, high-volume flow of data that is produced by a data source.

There are several types of hose designed specifically for the fire service. Those designed to operate under positive pressure are called discharge hoses; they include: attack hose, supply hose, relay hose, forestry hose, and booster hose. Those designed to operate under negative pressure are called suction hoses.

Hoses can also be classified by material. Common types of hose material include metal, rubber, PVC, PTFE, and composite.

The outside layer is made of fire resistive Kevlar/Nomex with Ripstop weave. The inner layer is a thermal layer with a moisture barrier. The yellow and silver stripes that you see are reflective. They allow firefighters to be seen when lights shine on them in the dark.

Hose reel cylinders are made of metal, fiberglass, or plastic. The most common types is spring driven, which self retracts. Other varieties include hand crank and motor driven.

The two woven polyester jackets covering the rubber tube of a double jacket fire hose provide a higher pressure rating and are treated to resist mold, mildew, and abrasion. The double jacket fire hose, on average, offers twice the service life of a single jacket fire hose.

Features & Benefits of Rubber hose

Durability: Resistant to abrasion, impact, and most chemicals, rubber hoses can withstand harsh environments and heavy use over a long period of time. Temperature resistance: Rubber hoses can be designed to withstand high or low temperatures, depending on the specific application.

Today, most fire hoses are made of a nitrile rubber tube that is insulated by a woven polyester fabric jacket instead of the cotton fire hose canvas used in the past.

The Brigadier Type 3 layflat fire hose is characterised by its heavy duty, high abrasion resistance and extremely long service life. Flexible and kink resistant structure produced with very low twist, it is a multipurpose hose suitable for a wide range of applications.