What is Minwax Pre-Stain Wood Conditioner?

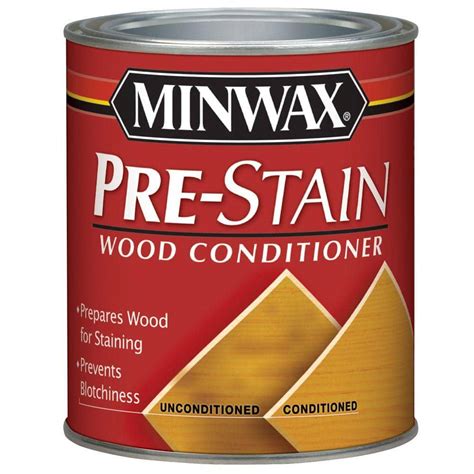

Minwax Pre-Stain Wood Conditioner is a popular product among woodworkers and DIY enthusiasts alike. It is a clear liquid that is applied to bare wood prior to staining, and its purpose is to help even out the absorption of the stain and prevent blotchiness.

The Pre-Stain Wood Conditioner works by penetrating the wood fibers and temporarily sealing the surface, preventing the stain from being absorbed unevenly. This is particularly important for softwoods such as pine or fir, which tend to absorb stain unevenly and can result in a blotchy appearance if not prepared properly.

To use Pre-Stain Wood Conditioner, it is important to apply it liberally using a clean brush, rag, or sponge. The conditioner should be left on the surface for 5-15 minutes before wiping off any excess with a clean, dry cloth. It is essential to wait until the conditioner is completely dry before applying any stain to the wood.

Once the conditioner has been applied, the wood will be ready for staining, and the results should be a much more even and consistent color. The product is available in both oil-based and water-based formulas, making it compatible with a wide range of stains.

One thing to keep in mind when using Minwax Pre-Stain Wood Conditioner is that it will slightly lighten the natural color of the wood, so it is important to choose a stain that is slightly darker than the desired finished color. Overall, using a wood conditioner like this can help achieve a more professional and polished finish in any woodworking or staining project.

Frequently Asked Questions about minwax pre-stain wood conditioner

Minwax® Water-Based Pre-Stain Wood Conditioner penetrates the grain of the wood to promote uniform acceptance of water-based wood stains and helps control the effect of grain raising on both soft and hard woods. Minwax® Water-Based Pre-Stain Wood Conditioner 4.9 out of 5 stars, average rating value. Read 60 Reviews.

Now for any water-based stain. Project you'll want to use our water-based pre-stain wood conditioner as your first. Step it prepares all types of wood for staining.

Pre-stain wood conditioner: stir well, apply using foam brush, wipe using dry rag to remove excess, wait a few minutes, wipe with wet rag, wipe with dry rag. Sand after pre-stain at 320 grit using orbital.

Wood conditioner is an ultra-thin layer of finish that reduces stain penetration in softwoods. This results in a more uniform and desirable result when staining wood. Not all wood requires wood conditioner, but most softwoods benefit from it.

Pre-stain wood conditioner prepares the wood to receive the stain in a uniform way. I know conditioning is an extra step that may just seem like a hassle, but depending on the longevity of the project, it's absolutely worth it.

Wood conditioner (sometimes called pre-stain) helps wood absorb stains more evenly. What is this? Bare wood has natural variance in the dryness of its surface. Drier spots on the piece of wood will absorb more stain, making them turn darker in color.

As we mentioned, you don't want to wait too long before applying the wood stain to your project. Waiting longer than two hours to apply the stain after the conditioner can degrade the conditioner's efficacy, leading to an uneven finish.

To help even out the color when working with bare woods, you can try using a pre-stain wood conditioner. The conditioner works by penetrating and temporarily sealing the wood to even out the rate of absorption, thereby creating a much more uniform stain coat.

Pre-stain wood conditioner prepares the wood to receive the stain in a uniform way. I know conditioning is an extra step that may just seem like a hassle, but depending on the longevity of the project, it's absolutely worth it.

Expert Tips For an Extra Smooth Finish:

A sanding sealer is not the same as a wood conditioner. Whereas a wood conditioner is a pre-stain treatment that reduces blotchiness when staining, a sanding sealer is applied only to bare wood that is not going to be stained.

The more important the project, the more important the Pre-Stain Conditioner. The more porous woods, such as pine and alder, are the most unpredictable when it comes to staining. Give these woods a second coat of Minwax® Pre-Stain Wood Conditioner to further reduce blotchiness.

The point of a pre-stain conditioner is to prevent stained wood from looking mottled or blotchy because some areas are more porous and absorb more stain than other areas. The conditioner reduces that effect by sealing the wood to some degree so that it absorbs stain more evenly.

Wood stained without a wood conditioner can end up looking splotchy or blotchy. Store-bought pre-stain conditioners help wood to accept stain more evenly, but they have some drawbacks. They cause the color of the stain to be lighter.

Let Pre-Stain Conditioner dry at least 30 minutes, but no longer than 2 hours before applying stain, in ideal conditions: 70°F/20°C; 50-70% humidity. Do not wait longer than 2 hours, and never let Pre-Stain Conditioner dry overnight before applying a stain over it.

The more important the project, the more important the Pre-Stain Conditioner. The more porous woods, such as pine and alder, are the most unpredictable when it comes to staining. Give these woods a second coat of Minwax® Pre-Stain Wood Conditioner to further reduce blotchiness.

7. Let Pre-Stain Conditioner dry at least 30 minutes, but no longer than 2 hours before applying stain, in ideal conditions: 70°F/20°C; 50-70% humidity. Do not wait longer than 2 hours, and never let Pre-Stain Conditioner dry overnight before applying a stain over it.