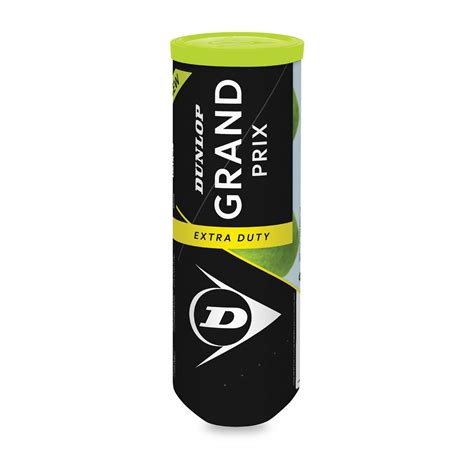

What is Dunlop Grand Prix Hard Court Tennis Balls?

Dunlop Grand Prix Hard Court Tennis Balls are a popular choice among professional and amateur tennis players alike. Made with high-quality materials, these tennis balls offer great durability and consistent performance, making them perfect for competition play or training sessions.

The Dunlop Grand Prix Hard Court Tennis Balls are specifically designed for hard court surfaces, providing excellent bounce and responsiveness. The felt surface of these tennis balls is made from woven wool and synthetic materials, which helps to increase their resistance to wear and tear, ensuring they last longer than other tennis balls on the market.

These tennis balls have been tested and approved by the International Tennis Federation (ITF), which means that they are also suitable for use in official tournaments. They come in a standard size and weight, ensuring that they meet the standards for professional competition.

Many tennis players who have used Dunlop Grand Prix Hard Court Tennis Balls praise their consistent bounce, stating that they are ideal for practicing different shots, as well as for playing matches. The balls are well-balanced and comfortable to play with, and the felt surface has a good grip, allowing players to maintain control over their shots.

In summary, Dunlop Grand Prix Hard Court Tennis Balls are a great choice for anyone looking for reliable, durable, and high-performing tennis balls. They offer excellent bounce, control, and responsiveness on hard court surfaces, making them perfect for players of all levels who want to improve their game, or play in official competitions.

Frequently Asked Questions about dunlop grand prix hard court tennis balls

The main difference between regular-duty and extra-duty tennis balls is that extra-duty balls, also known as "hard court" balls, have a thicker and more durable felt covering, so they're meant to last longer on hard surfaces.

WILSON Legacy All Court Roger Federer.

The reason new balls are sold in plastic canisters is to prolong their shelf life, to keep them as "fresh" as possible until you are ready to play with them. The canister keeps them under about 15 lb of pressure equal to the internal pressure so they dont lose air while in the can.

The modern ball, mostly made in optic yellow colour, has a diameter between 2.575 inches and 2.7 inches and weigh between 56 grams and 59.4 grams. The balls today are made by compression molding of a rubber compound into two separate half-shells which are then assembled together to produce a core.

Often made from macadam or concrete, hard courts are the most neutral of tennis courts. In terms of speed, it's faster than clay and slower than grass, but the bounce is a lot higher due to the harder surface.

As you might guess, tennis balls travel slower on clay courts than they do on hard courts or on grass. The clay absorbs the impact of the ball more readily. Regular-duty balls therefore have a thinner and less fuzzy felt covering so that the balls will pick up less clay when used on those courts.

Dunlop tennis balls

Welcome to the world of Dunlop tennis balls, used around the globe from recreational courts to Grand Slam stadiums.

Modern tennis balls must conform to certain size, weight, deformation, and bounce criteria to be approved for regulation play. The International Tennis Federation (ITF) defines the official diameter as 6.54–6.86 cm (2.57–2.70 inches). Balls must have masses in the range 56.0–59.4 g (1.98–2.10 ounces).

In the late 1920s Thomas E. Wilson & Co. and the Pennsylvania Rubber Company, respectively, began manufacturing the first pressurized metal tubes for preserving the shelf life of tennis balls. The air pressure in the can was increased to equal the pressure in the ball.

Tennis balls are filled with air and are surfaced by a uniform felt-covered rubber compound. Tennis ball felts comprise wool, nylon, and cotton in a mixture surrounding the rubber edge. The felt delays flow separation in the boundary layer which reduces aerodynamic drag and gives the ball better flight properties.

The ball is placed in a moulding press and heated, curing together the rubber solution on the core and that on the back of the cloth. The heat and pressure also cure the rubber solution in the join between the two covers and moulds it into a smooth seam. The moulded ball is cooled and removed from the press.

The company entered the sporting goods market in 1910, when it began to manufacture rubber golf balls at its base in Birmingham. The company introduced the Maxfli golf ball in 1922. Dunlop extended into tennis ball manufacture in 1924. In 1925, F A Davis was acquired, which had tennis racket manufacturing expertise.

Hard courts are generally made of synthetic or acrylic layers laid on top of a concrete or asphalt foundation. Resin and rubber are also used in some constructions.

noun. : a tennis court with a paved surface (as of asphalt or concrete) distinguished from clay court and grass court.

Hard surface courts have lower energy absorption than clay courts, making the tennis ball bounce higher and move faster. Hard courts are an all-around court, which makes them ideal for most types of tennis players.

Hard courts

In terms of speed, it's faster than clay and slower than grass, but the bounce is a lot higher due to the harder surface. It's the most common surface on the professional circuit and is used at the US Open and Australian Open Grand Slams.